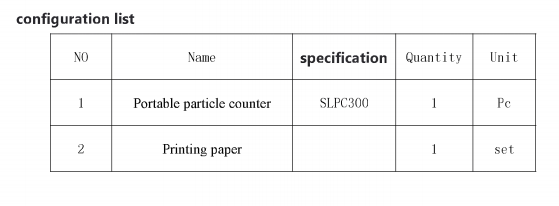

Portable oil particle counter SLPC300

Portable oil particle counter SLPC300

Product overview

SLPC 300 oil analyzer is used to regularly monitor and track the number and size of particles in the medium of hydraulic oil, lubricating oil, transformer oil (insulation oil), turbine oil (turbine oil), gear oil, engine oil, aviation kerosene, mineral oil, synthetic oil, lipid phosphate oil and water solution used in military equipment, and measure the particle size of particles in oil samples. And count according to the pre-selected particle size range, and can also detect the content of water in the oil sample, so as to obtain important information about particle size distribution and water content, equipment oil wear pollution monitoring and fault diagnosis analysis, is an important technology to assess the degree of solid particle pollution of the military equipment hydraulic system. In order to ensure the safety, reliability and combat effectiveness of military equipment in peacetime and wartime, it is an important necessary guarantee means.

The SLPC 300 oil analyzer is an instrument suitable for both field testing and laboratory analysis. The instrument uses the principle of photoresistance method to measure the size and quantity of small particles of pollutants in the liquid medium and the water content of the oil.

The high pressure interface can be directly connected to the hydraulic system or equipment for online monitoring, with a maximum pressure of 350bar; The low pressure interface allows extraction of bottled samples. Precision plunger pump, strict control of sampling volume accuracy, low viscosity or high viscosity oil offline or online testing.

SLPC 300 oil analyzer calibration according to ISO 11171:2010 (GB/T 18854-2015), ISO 4402:1991 two standards, support including ISO 4406 and NAS 1638 including a variety of testing standards, users can also set their own testing standards. Eight detection channels provide users with a wide range of choices. The use of oil analyzer is an effective analytical means to detect particulate contamination in liquids, and can also detect the water content of lubricating oil.

Performance description

The International hydraulic Standards Committee specified the light resistance (blocking) method test principle high-precision laser sensor, wide test range, stable performance, low noise, high resolution and high precision metering pump sampling method, injection speed can be adjusted, high sampling volume precision pipeline using 316L and PTFE materials to meet all kinds of organic solvents and oil detection for laboratory or field measurement. Built-in pressure relief device for online high pressure measurement can be connected to the external pressure chamber to form positive/negative pressure, to achieve the detection and degassing of high-viscosity samples can use a variety of sampling containers such as standard sampling bottles, sampling cups, or directly connected to the hydraulic system, to meet the detection requirements of different industries built-in multiple calibration curves, Compatible with all common domestic and foreign standards for calibration built-in GJB-420A, GJB-420B, NAS1638, GB/T14039, IS04406, SAE4059cpc, SAE4059F, SAE749D, r T17216, QC/T29104, JB/T9737, DL T432, HH005-2018 and other commonly used standards, a test can give all the built-in standards under the data results and water content, support custom standard testing, and can be set according to customer needs required standards can be set up 1000 particle size channels, easy to perform particle size analysis built-in data analysis system, can automatically determine the sample grade according to the standard, With automatic data processing, printing function color touch screen operation, dual interface in Chinese and English, with preset, input, modify, storage functions, easy and fast operation, can be connected to the computer or laboratory platform for data processing, can also use USB data storage built-in lithium battery, no external power supply can be used.

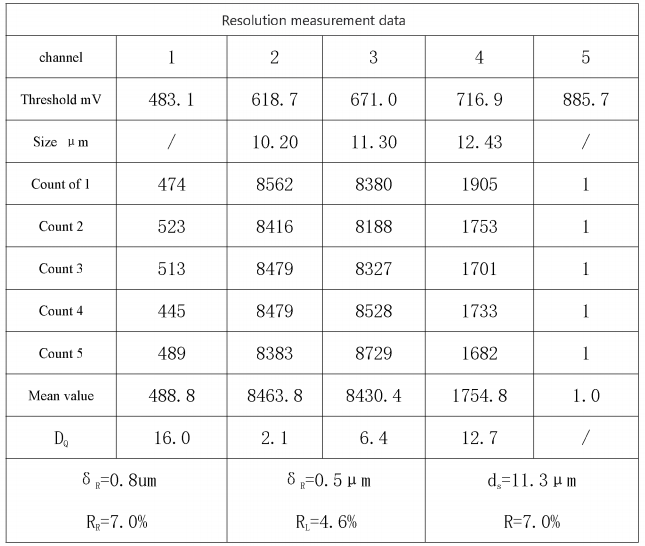

Technical indicators

1. Particle size range 0.5-600Wiim(IS04402) l-7〇 Wn (C)(IS011171)

2. Particle size channel 8

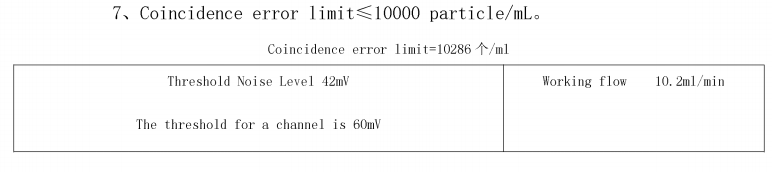

3. Maximum detection concentration 12000 particle/ml

4. Flow rate 30ml/min

5. Pressure range 〇-〇 .4MPa (can be extended to 35MPa through external pressure reducing valve)

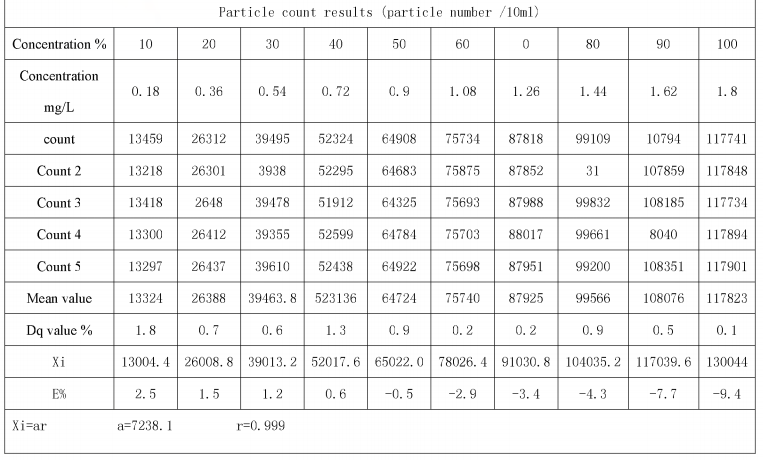

6. Sampling volume accuracy ±3%

7. Particle count repeatability ±2%

8. Relative error of particle count is ±10%

9. Detection of liquid viscosity < 200cSt

10. Sample temperature ^80° C

11. Power AC 220V ±10%, 50HZ

12. Battery life is 8 hours

13. Data output RS232 interface, USB interface, built-in printer

14. Display 5-inch LCD color touch screen

15. Dimensions 490 (L) X 200(H) X 360 (W)mm

16. Weight 9. 2kg

17. Use environment 〇-50°C

18. Measuring range: 0. 8um ~ 600um.