ONH-506 ONH-Analyzer

ONH-506 ONH-Analyzer

The instrument is based on pyroelectric sensor and thermalconductivity detector technology. Inert gas fusion method is used torapidly measure oxygen and nitrogen content in steel, rare earth materials,alloys, copper, zirconium, titanium, ceramics, powder materials and otherinorganic materials.

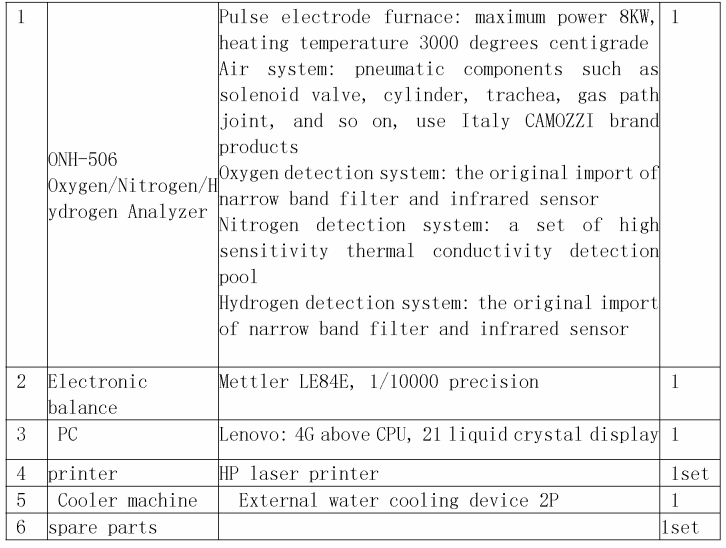

Instrument composition

The instrument consists of a pulse furnace infrared detection unit,a computer, an electronic balance, a printer, and a cold water machine.

Specification

Range:

Oxygen: 0. 5ppm -20%

Nitrogen: 0. 5ppm - 30%

Hydrogen: 0. 2ppm - 0. 1%

Note: change the size of the sample to change the range of measurement

Precision: Oxygen: 1ppm or 1% RSD, whichever is greatr

Nitrogen: 1ppm or 1% RSD, whichever is greatr

Hydrogen: 0. 2ppm or 2% RSD, whichever is greatr

Note: not greater than the standard deviation or uncertainty of thesample.

Readability: 0. Olppm

Analysis time: 120-240S

Electronic balance weighing precision: 0.OOOlg

Detection methods: Oxygen: non dispersive infrared absorption method

Nitrogen: thermal conductivity detection

Reagents: Anhydrous magnesium perchlorate(MgC104), Sodium Hydroxide onan inert base , rare-earth copper oxide

Electrode pulsing furnace: 220VAC, maximum power: 8KVA, maximum current 1500A, maximum temperature:3000 C

Gasses required:

Carrier gas: high purity helium gas 99.99%, 0. 20

MpaPower gas: ordinary nitrogen (or purified compressed air), 0. 35

MpaCooling system: external circulation cooling system, 2 pieces, refrigerating capacity 5200W.

Working environment: 15-35 centigrade, 20-80% relative humidity.

Instrument size: the host W 600 x D700 x H 900.

Instrument weight: 160 KG.

Power supply: 220V, 50HZ, single phase, 50A

Main configuration

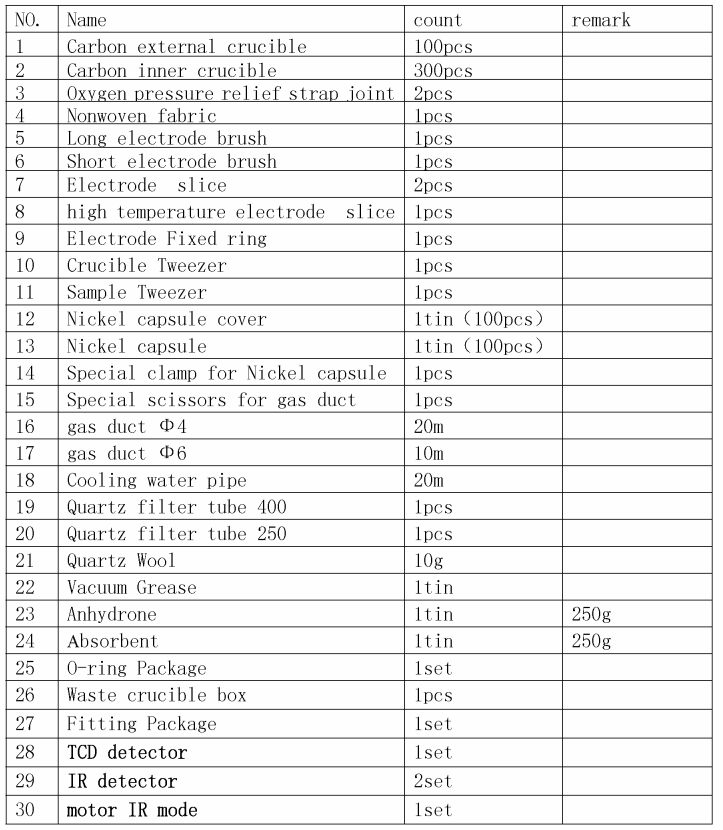

Spare parts List